Blog

Why we don't sell our Props

by Carmen - Director of The Prop Factory

Tuesday 18th February 2020 10:01:58

People quite often want to buy our props. We’ve had requests from someone in the USA to buy our Mary Poppins replica carpet bag as a Christmas present; someone who owned the same botanical tall bistro table as us but wanted a replacement as theirs had gone rusty from being left outside;

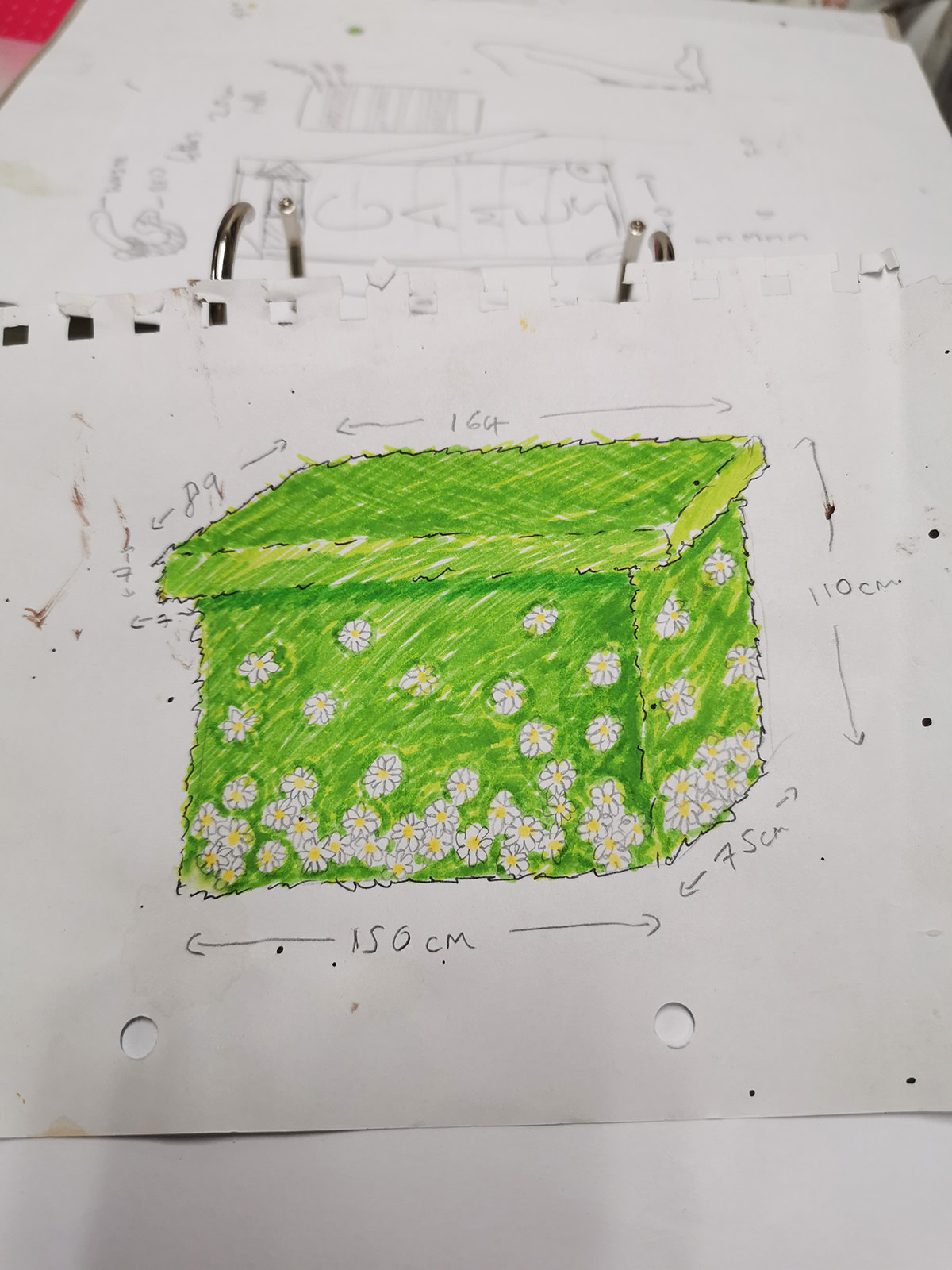

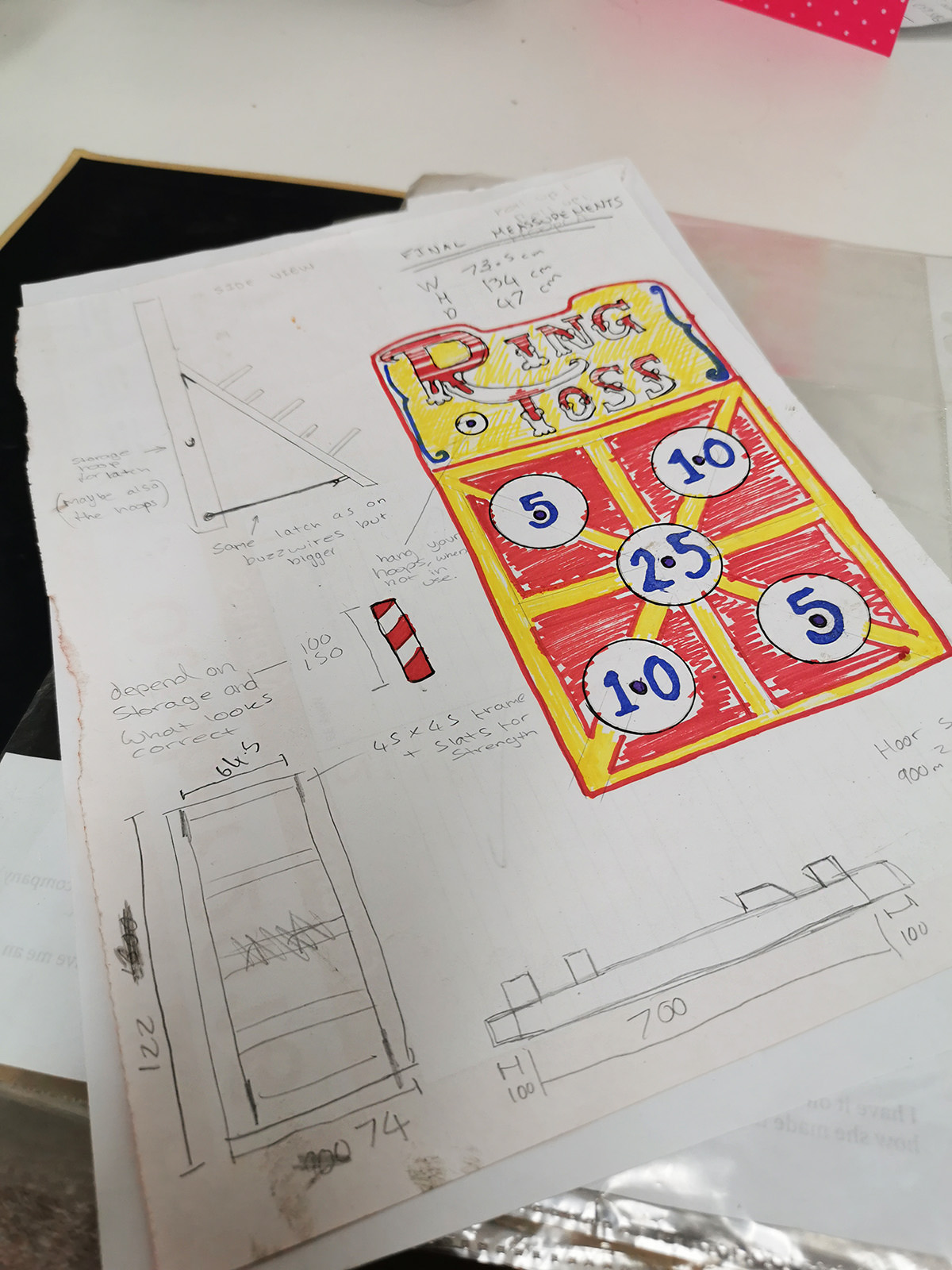

a brewery that wanted all our festival ribbon bunting; and it feels like just about everyone wants our fake but realistic straw bales, giant flowers, fairground games and circus props!

a brewery that wanted all our festival ribbon bunting; and it feels like just about everyone wants our fake but realistic straw bales, giant flowers, fairground games and circus props!

We thought it was time to set the record straight and give an honest and detailed answer about why we don’t sell our props... and it might not be the most obvious answer!

We thought it was time to set the record straight and give an honest and detailed answer about why we don’t sell our props... and it might not be the most obvious answer!

Having said that, let's get the obvious out of the way first. Our collection is truly unique. We offer something exclusive to our customers that you won't find anywhere else and we like it that way. We aren't just building random props - it's a curated collection where we constantly add to our styling themes using our library of colours and trademark design traits. If you read our blog How to recognise a Prop Factory prop, you'll see how seriously we take our prop making.

If you read our blog How to recognise a Prop Factory prop, you'll see how seriously we take our prop making. We make to hire not to sell, there is a big difference. There are lots of reasons that we make the vast majority of our products. At first, it was pure necessity. It is pretty much impossible to buy off-the-shelf versions of our products. You can't just drop into the 'prop department store' and fill up your trolley with bits for every theme - there just isn't enough consumer demand to warrant that kind of store.

We make to hire not to sell, there is a big difference. There are lots of reasons that we make the vast majority of our products. At first, it was pure necessity. It is pretty much impossible to buy off-the-shelf versions of our products. You can't just drop into the 'prop department store' and fill up your trolley with bits for every theme - there just isn't enough consumer demand to warrant that kind of store. There are, of course, a few places where you can buy themed props but they tend to be at opposite ends of the spectrum - either very cheaply made or incredibly expensive. If you do come across a cheap but good quality prop then it is quite often second hand but bargains like this are few and far between.

There are, of course, a few places where you can buy themed props but they tend to be at opposite ends of the spectrum - either very cheaply made or incredibly expensive. If you do come across a cheap but good quality prop then it is quite often second hand but bargains like this are few and far between. We didn't start out to be a prop making company - we were going to be a prop hire company but almost immediately we found that it was so hard to 'just buy things'. So we started making. Some of the first props we made were our seaside peep board, pointy hand signs, vintage photo wall, lemonade stand and kissing booth.

We didn't start out to be a prop making company - we were going to be a prop hire company but almost immediately we found that it was so hard to 'just buy things'. So we started making. Some of the first props we made were our seaside peep board, pointy hand signs, vintage photo wall, lemonade stand and kissing booth.

Over the years I have seen the odd peep board for sale but none of the rest of these items. I totally understand why people ask to buy items, because if you are not a person who makes things, or knows some ‘makers of things’ then it is very hard to find what you need.

Over the years I have seen the odd peep board for sale but none of the rest of these items. I totally understand why people ask to buy items, because if you are not a person who makes things, or knows some ‘makers of things’ then it is very hard to find what you need. I’ve noted that all big prop companies have a dedicated prop making department and, not only that, they produce a large quantity of their own props. It seems that, to make it in prop hire you must have a prop making orientation.

I’ve noted that all big prop companies have a dedicated prop making department and, not only that, they produce a large quantity of their own props. It seems that, to make it in prop hire you must have a prop making orientation. Another reason we make our own products is because off-the-shelf items, and even second hand props, aren’t built with hire in mind. Props sold in shops for events like Halloween are made solely for immediate profit which is where ours are different. It would be wrong to say that we don't have profit in mind too, but we don’t have that single opportunity to make a profit therefore the way we produce items is entirely different to retail. We need to make sure our products last for years and years, with our minimum prop lifespan being at five, if not 10, years. Can you imagine how many of the things you've bought recently will still be in existence in 10 years time? Our materials have to be as robust as possible, as cheap wood, like MDF, just won’t last long enough.

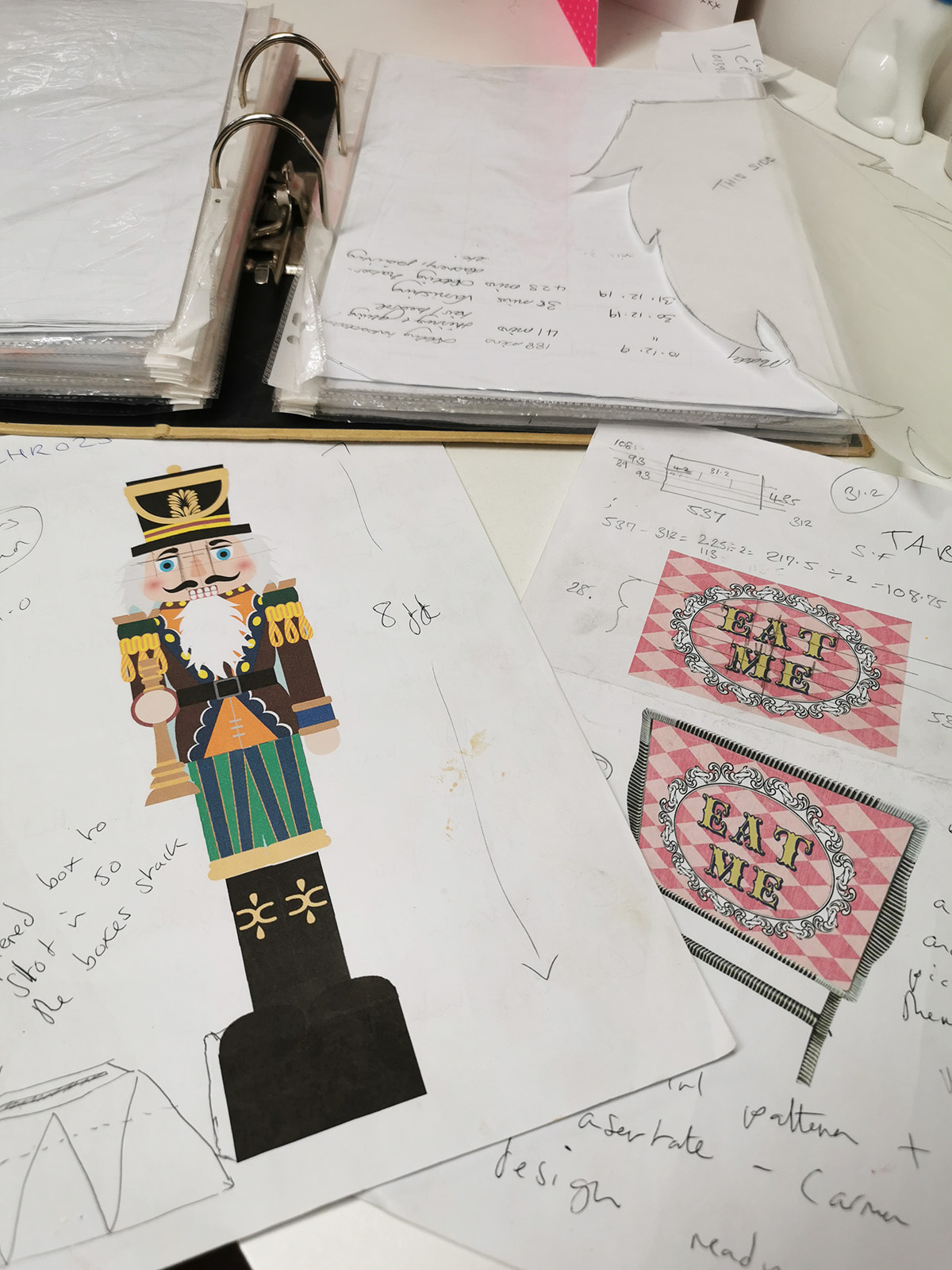

Another reason we make our own products is because off-the-shelf items, and even second hand props, aren’t built with hire in mind. Props sold in shops for events like Halloween are made solely for immediate profit which is where ours are different. It would be wrong to say that we don't have profit in mind too, but we don’t have that single opportunity to make a profit therefore the way we produce items is entirely different to retail. We need to make sure our products last for years and years, with our minimum prop lifespan being at five, if not 10, years. Can you imagine how many of the things you've bought recently will still be in existence in 10 years time? Our materials have to be as robust as possible, as cheap wood, like MDF, just won’t last long enough. Our assembly processes are often more lengthy with parts being fabricated so they stay together. For example, we purchased some second hand nutcrackers, that were originally from a retail store and spent a considerable amount of time taking them apart and putting them back together so if they were to fall from height they wouldn’t break. Each of these is now on our inventory as a nutcracker on very tall plinth. You can't see the extra work that has gone into securing every joint, as the holes we made to do so have been filled, colour matched and varnished.

Our assembly processes are often more lengthy with parts being fabricated so they stay together. For example, we purchased some second hand nutcrackers, that were originally from a retail store and spent a considerable amount of time taking them apart and putting them back together so if they were to fall from height they wouldn’t break. Each of these is now on our inventory as a nutcracker on very tall plinth. You can't see the extra work that has gone into securing every joint, as the holes we made to do so have been filled, colour matched and varnished. The way we design products means they are often engineered to a far higher standard than you receive from a bought item. They flat pack and use no tools to assemble (IKEA we beat you on that one for sure!). The paintwork or fabric has protective finishes, and these protective coatings have to be topped up. Products have to be designed to consider how they will age when they are stored - they need to be UV stable, with anti-crease fabric, non-rust metal, dirt repellent, and not hold moisture. These are just a few of the storage considerations. Parts of props can’t snap off, get squashed, smash, bend, rip, fray, upwrap, or come loose.

The way we design products means they are often engineered to a far higher standard than you receive from a bought item. They flat pack and use no tools to assemble (IKEA we beat you on that one for sure!). The paintwork or fabric has protective finishes, and these protective coatings have to be topped up. Products have to be designed to consider how they will age when they are stored - they need to be UV stable, with anti-crease fabric, non-rust metal, dirt repellent, and not hold moisture. These are just a few of the storage considerations. Parts of props can’t snap off, get squashed, smash, bend, rip, fray, upwrap, or come loose. Props can’t be too heavy, too big, too small, have too many parts, or be too long. Props have to be safe when a customer uses them so no high centres of gravity, minimal trapping and tripping risk, no risk of falling parts, snapping rope, electrical shock and such. Each prop has a 25 point risk assessment. They have to be easy to transport and to store. Not to mention easy for us to fix if they break, although of course we try everything we can in the making process to minimise the chance of them breaking.

Props can’t be too heavy, too big, too small, have too many parts, or be too long. Props have to be safe when a customer uses them so no high centres of gravity, minimal trapping and tripping risk, no risk of falling parts, snapping rope, electrical shock and such. Each prop has a 25 point risk assessment. They have to be easy to transport and to store. Not to mention easy for us to fix if they break, although of course we try everything we can in the making process to minimise the chance of them breaking.

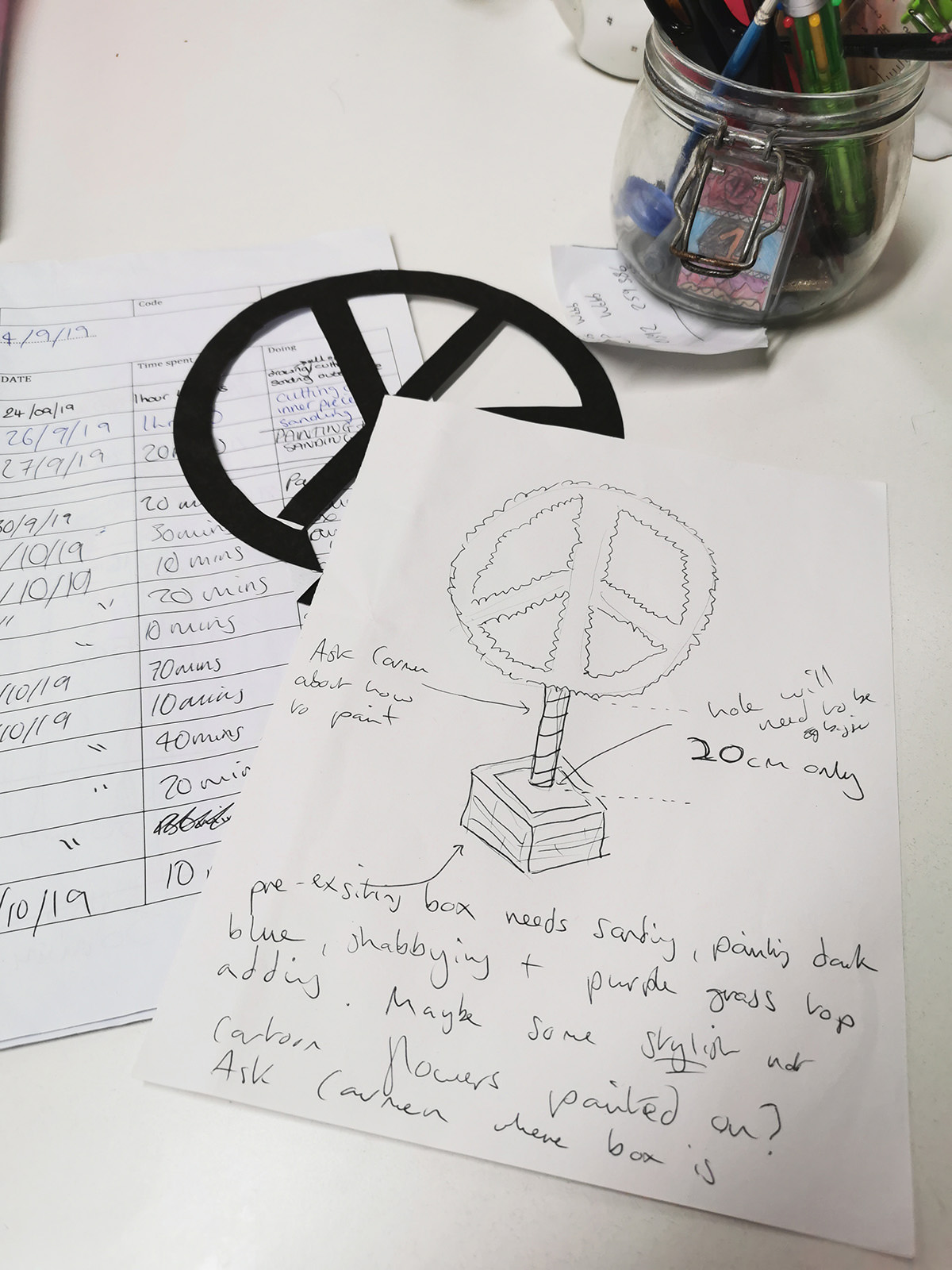

Aside from the practical considerations there is also the aesthetic. We don’t want props like anyone else. We never ever copy props from other companies or duplicate creations found on Pinterest. We strive for original, unique ideas that are true spectacles of imagination. On top of all this the props have to be sustainable too. There is so much to consider when designing and making props that the process is quite costly. And then we only make a few of each item so our cost to bring an item into fruition can be ten times or even more than the price it would cost to buy an equivalent version of the prop in a shop. Take, for example, in the summer I have noticed many supermarkets now sell garden games for less than we hire them. They might on the surface be the same product but one is built for retail, for home use, and one is built for events. We build for events.

If we wanted to sell our products we’d have to completely change how we make items based on selling each item once not hiring it for years. From our experience people just aren't prepared to pay what it costs to make our items. Take, for example, our fake straw bales. The production cost in labour and materials only, so not including tools and workshop space, is just shy of £150 per bale. Say we decided to sell them for £200 - each could generate a tiny £50 profit you'd think. However, we’d have to add VAT making their retail price £240 each. That £50 'profit' would soon be sucked up by the cost of admin staff, marketing, the design process, logistics, storage and all the other overheads that come with a business. There really wouldn’t be any money left from that £50. I suspect if someone asked to buy 10 fake straw bales and we said 'that will be at least £2400' they might be very shocked!

The production cost in labour and materials only, so not including tools and workshop space, is just shy of £150 per bale. Say we decided to sell them for £200 - each could generate a tiny £50 profit you'd think. However, we’d have to add VAT making their retail price £240 each. That £50 'profit' would soon be sucked up by the cost of admin staff, marketing, the design process, logistics, storage and all the other overheads that come with a business. There really wouldn’t be any money left from that £50. I suspect if someone asked to buy 10 fake straw bales and we said 'that will be at least £2400' they might be very shocked! Even when people ask us to do commission work, our staff are trained to build for quality and longevity so it would be very difficult to switch to a different mentality. Which brings me onto another reason why we don’t sell our products and that is sustainability.

Even when people ask us to do commission work, our staff are trained to build for quality and longevity so it would be very difficult to switch to a different mentality. Which brings me onto another reason why we don’t sell our products and that is sustainability.

The beauty of a hire company is that it is more sustainable for lots of people to hire the same item rather than each person to buy that item. We are all about sustainability, that is our USP and the reason we do what we do. So selling items just goes against our values as a company. It is as simple as that.

Lastly, we just don’t have the capacity to make items to sell. We get asked all the time to sell items, and if we chose to do so we’d need more space, more staff and more resources. We plan our prop-building schedule six to 12 months in advance. We do extensive research as to what to build in the coming year. We ask for feedback and input from our customers, and have built our own prop hire analytics software. Then we spend days and weeks inventing products, thinking up new ideas for props to hire. Thinking of solutions for event dilemmas, again back to the straw bales as an example as if hiring real straw bales isn’t an option but you still want that rustic look then we have lightweight, flatpack, hypoallergenic, dust mite free ones that look exactly like the real thing. Then we decide our prop making budget and allocate every available prop making hour for the entire year to make all our new products. We have no room left in hours or space to make extra products to sell. We have found making products to sell is actually counterproductive and puts a real spanner in the works (pardon the pun) of our prop making flow.

Then we decide our prop making budget and allocate every available prop making hour for the entire year to make all our new products. We have no room left in hours or space to make extra products to sell. We have found making products to sell is actually counterproductive and puts a real spanner in the works (pardon the pun) of our prop making flow.

So in a nutshell, we don’t make products to sell because we don't have the time or space, it goes against our sustainability values, we build our products differently to how you’d build a product to sell and, of course, we want to keep our collection completely unique and exclusive to our customers.

See all the props featured in this blog in one place here.

Carmen x